This is me documenting my quest to design the quietest soundproof box for portable generators. I did a lot of research and put some science into this design. For those of you who watched the video and are curious about how much it costs, weighs, and what parts I used, check out the list below.

Soundproof Box Stats

- Weight: 241 pounds

- Final cost: $368

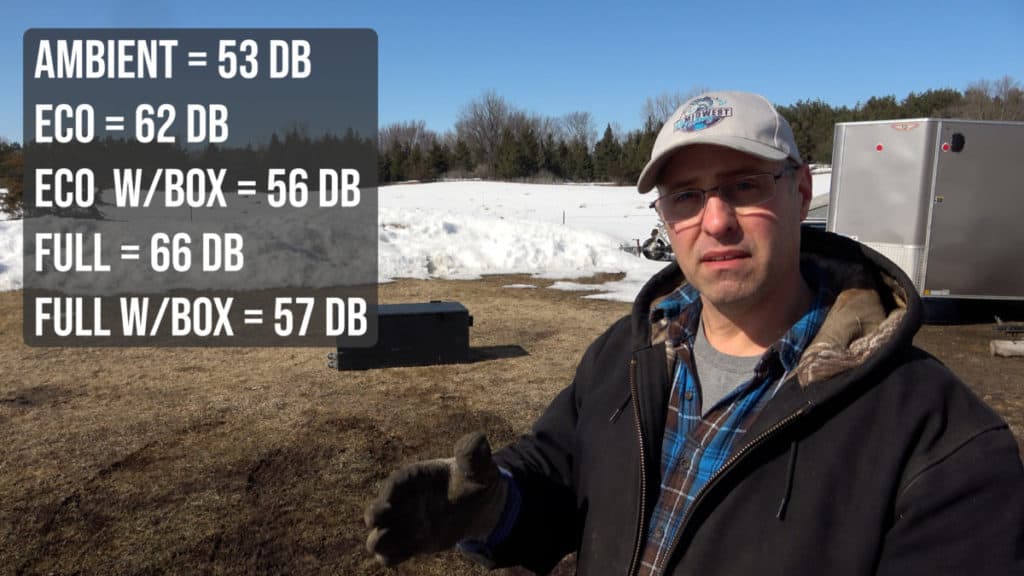

- Sound Reduction: Up to 9 db (Almost 100 times quieter)

- Size: 4 feet long x 2 feet wide x 21 inches tall

Parts List for Soundproof Box

- 3/4 inch OSB 2’x8′(wood) = $65.96 (4@ $16.49)

- 5/8 in drywall 4’x8′ sheet = $14.28

- Mineral wool insulation, 15.25″ x 47″ x 3″ = $52.98

- 3″ caster wheels = $13.98 (2@ $6.99)

- Acoustic sealant = $15.98 (2@ $7.99)

- Rubber stall mat = $61.05

- Outlet box cover = $1.78

- 3′ extension cord = $4.99

- 3′ power supply cord = $3.45

- Bolts/ Hardware = $34.49

- Rubber undercoating = $12.87

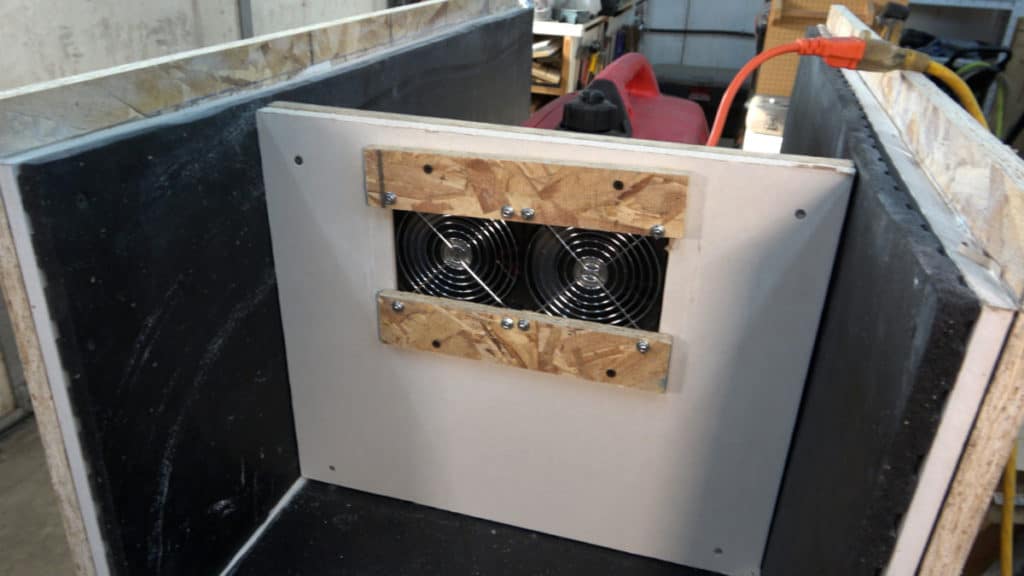

- AC cooling fans = $64.40 (2@ $29.99)

Free Parts I Already Had

- Screws

- Paint

- Primer

- Aluminum panels

- Aluminum tape

- Furnace grill (x2)

See the video below

The Build

Before any project, I like to do my research and learn as much as I can before starting.

For this project, I had to learn about how sound travels and how to control it. There are basically three things you can do with sound.

- Reflect it

- Absorb it

- Block it

Reflecting Sound

Imagine yourself in an empty room with hard walls. The sounds you make, bounce (or reflect) off the walls, making the room sound loud and full of echoes. This is what we want to avoid.

Absorbing Sound

To help make this room sound better, you can fill the room with sound absorbing materials. Things like, furniture, acoustic panels on the walls, blankets, or insulation. This prevents the sound from bouncing around and makes it sound quieter.

Blocking Sound

To keep sound from escaping the room, you will need to block it. For this, you will need heavy, dense materials, such as, concrete, wood, rubber or mass loaded vinyl.

Research

There is a lot of misinformation floating around on the internet, so you have to be careful about where you get your information. Google is a good place to start, but Google Scholar is where you can find good information that is backed by science.

At Google Scholar, the results that come back are from scientific journals and papers. It can be some heavy reading and sometimes hard to understand, but its very valuable information.

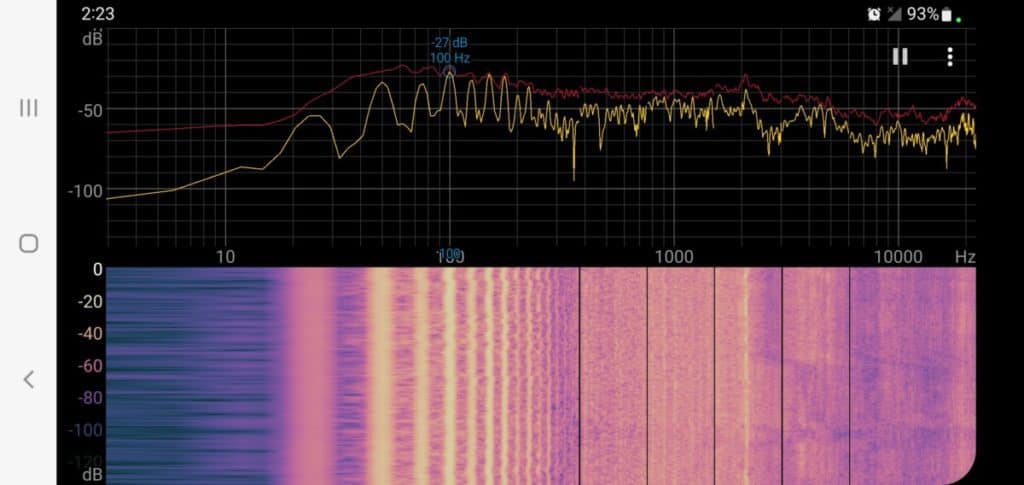

It is helpful to know the type of sound you are blocking. Luckily, there is an app for that. The one I used is called “Spectroid.” It will give you the range of frequencies you are trying to control. As you can see, the generator puts out a whole lot of frequencies, from about 50hz, to over 10,000hz.

The important thing to note here, is that low frequency sounds are much harder to block than high frequency sounds. The heavy dense materials are better at blocking those low frequencies, whereas the soft materials will absorb the high frequencies. We will be needing a combination of both for this build.

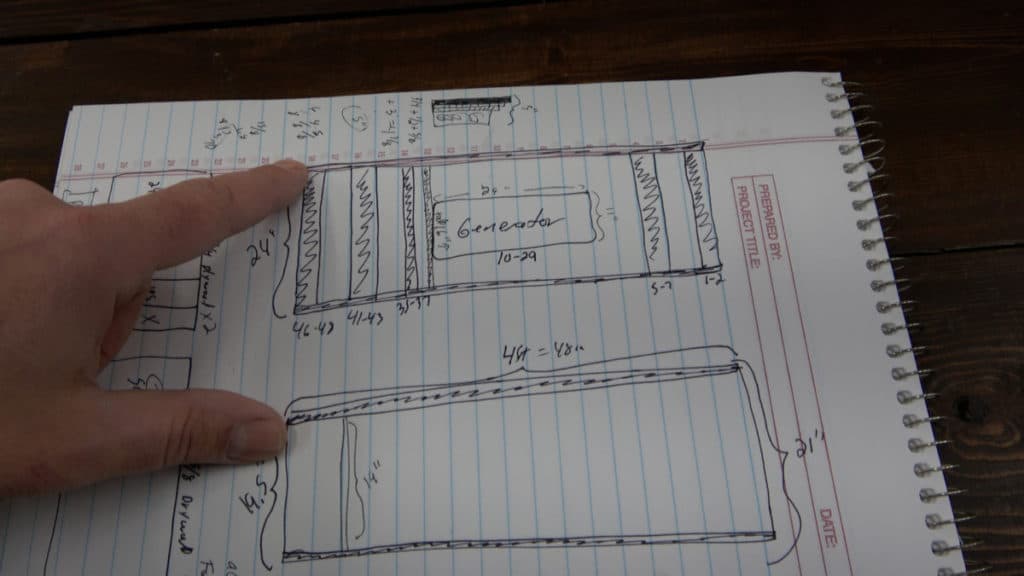

The Design

Before I start buying materials or physically building something, I like to sketch it out on paper first.

If all looks good, then I start a mock build with some scrap wood. Sometimes the dimensions on paper look better than real life. This gives me a better perspective on how big it actually is.

Material Selection

For this build, I want to absorb AND block the sound, so I will be using a combination of soft and heavy/dense materials.

The outer shell will be made up of three layers of dense materials to block the sound from escaping.

The outermost layer is 3/4 inch OSB (or plywood). Followed by 5/8 inch drywall. The inside layer will be 3/4 inch dense rubber (Actually a cow mat from Tractor Supply).

I will put a bead of acoustic caulk between each layer to keep sound from passing from layer to layer.

For the soft sound absorbing layer, I will be using mineral wool insulation. This is used in homes for its insulation and sound blocking properties.

The Finished Product

The finished product consists of a center chamber for the generator. Baffles on the front and rear for the air intake and exhaust. A power cord that runs to an outlet on the outside, two highspeed AC powered fans to move air through the box for combustion and cooling.

The video goes into much more detail as to how it was put together, but here are a few more pictures to show the design.

I wanted this box to be portable and to fit in the bed of my truck underneath my tonneau cover. I made the dimensions 4 feet long x 2 feet wide x 21 inches high.

Final Conclusions

You can see the results above. At full throttle, the box dropped the sound level by 9DB. That may not sound like a lot, but that is almost 100 times quieter!

The only sound getting through is a very low rumble that I can only detect at a close distance. I think its mostly coming from the generator vibrating the box. I put rubber feet on the box to help prevent vibration traveling through the box, but maybe there is something more I could do there.

Pros/Cons

I will start with the cons. Probably the biggest obstacle with this box is its weight. At 241 pounds, it takes two people to lift it into a truck. I’d like to experiment with lighter weight materials to see if I can get the same level of sound dampening, but with less weight.

The pros: It works very well. I brought it camping, and I was unable to hear it from about 1.5 campsites away. Most campsites will allow generator use as long as its below the 60DB level, which mine was.

This was the first prototype I made, and I feel like it was a success, but could use a few improvements. I might update it in the future, but for now, it works for me.